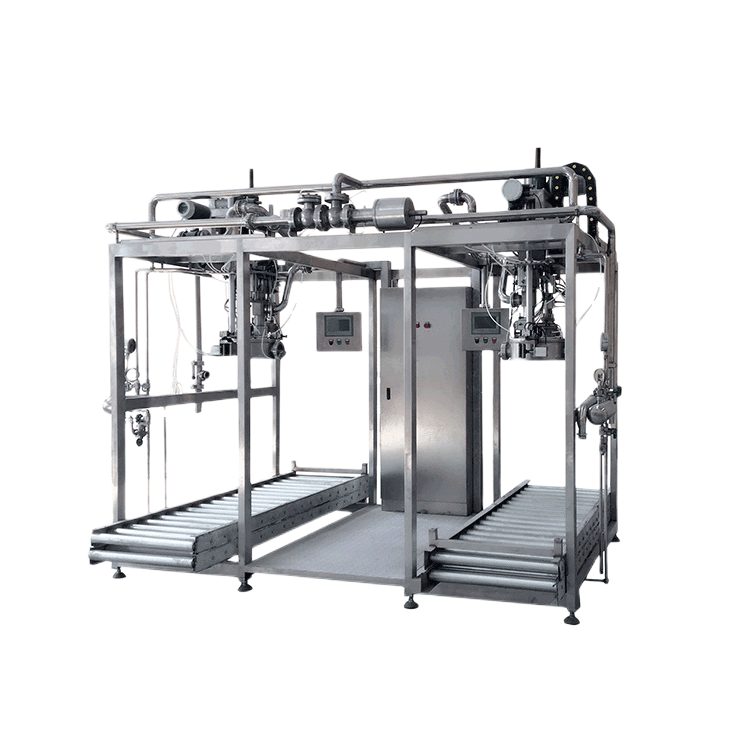

The unite is consisted of: aseptic filling head, accurate electronic balance, drum conveying roller, PLC Control system, control cabinet, steam barrier and protection system, operation platform, etc.

This filling machine is used for filling the fruit juice, paste, puree, pulp and other liquid into the aseptic bags for storage. The natural fruit juice or pulp can be kept in the aseptic bags

for more than one year under constant temperature, and the concentrated fruit juice or paste can be kept for more than two years.

The aseptic filling machine can be connected with the Sterilizer directly; the product will be filled into the aseptic bags after fully sterilized by the sterilizer.

The aseptic bags are aluminum compound multi-layer bags; it can cut off from sunlight and oxygen affection to guarantee the high quality of the products.

The temperature of filling chamber can be adjusted automatically by temperature control system, the bag’s spout and filling chamber will be sterilized by steam spraying.

Main characteristic:

1. Provide several security measures(position controlling, computation controlling, temperature controlling) to prevent the machine from destroying and guarantee the product's quality

2. Products' valves, filler head and other moving parts have steam barrier for protection

3. Keep the filling chamber sterilized all the time using steam protection

4. Easily adjustable with simple change parts according to the aseptic bag volume and size

5. When shifting the aseptic bag or some thing wrong with the filler, the product will be auto backtracked into the buffer tank before the UHT sterilizer.

6. Automatically print the black and white label and other data the customer specified such as the filling date, filling time, filling weight, product code or others, if you required.

7. Main structure with SUS304 stainless steel, combined Italy technology and based on Europe standard.

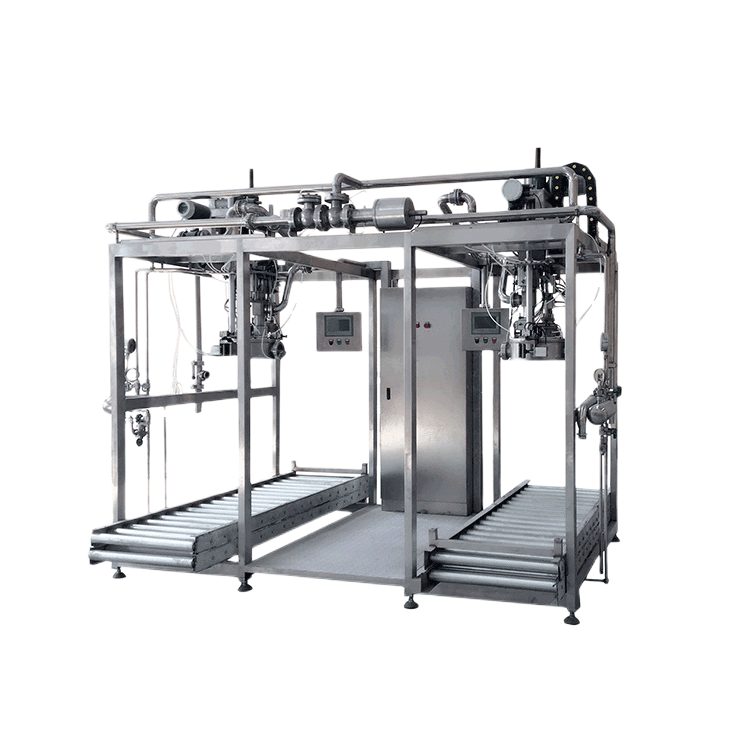

KROHNE Flowmeter

We use German brand KROHNE flow meter to ensure the precise control of flow.Designed based on Italian technology, updated during the 14 years’ experience.

Small floor area, high working stability, high precision.

High-quality Aseptic Filling Head

Siemens PLC control system, easy to operate, intuitive, with data recording function.

Applicable to different specifications of aseptic bags, can be customized according to the customer's filling mouth.

Reliable cover clamp design, stable operation of equipment, safe and reliable products.

Name | Single-head Filler | Double-head Filled | Double-head Filled | Single-head Filler | Single-head Filler |

Model | AF1S | AF2D | AF3D | AF5S | AF6D |

Capacity: t/h | 1-5 | 5-10 | 5-12 | 1-1.5 | 1.5-3 |

Power: Kw | 1 | 1 | 1 | 1 | 1 |

Steam Consumption: kg/h | 0.4-0.8 Mpa≈50 | 0.4-0.8 Mpa≈100 | 0.4-0.8 Mpa≈100 | 0.4-0.8 Mpa≈50 | 0.4-0.8 Mpa≈100 |

Air Consumption: m³/h | 0.6-0.8 Mpa≈0.04 | 0.6-0.8 Mpa≈0.06 | 0.6-0.8 Mpa≈0.06 | 0.6-0.8 Mpa≈0.04 | 0.6-0.8 Mpa≈0.06 |

Bag Size: Liter | 220 | 220 | 220, 1400 | 1 - 25 | 1 - 25 |

Bag Mouth Size | 1" |

Metering Method | Weighing Sensor or Flow Meter | Flow Meter |

Metering Error | Flow Meter:±0.2%~±0.5%, Weighing Sensor: ±1% |

Dimension: mm | 1700*2000*2800 | 3300*2200*2800 | 4400*2700*3500 | 1700*1200*2800 | 1700*1700*2800 |