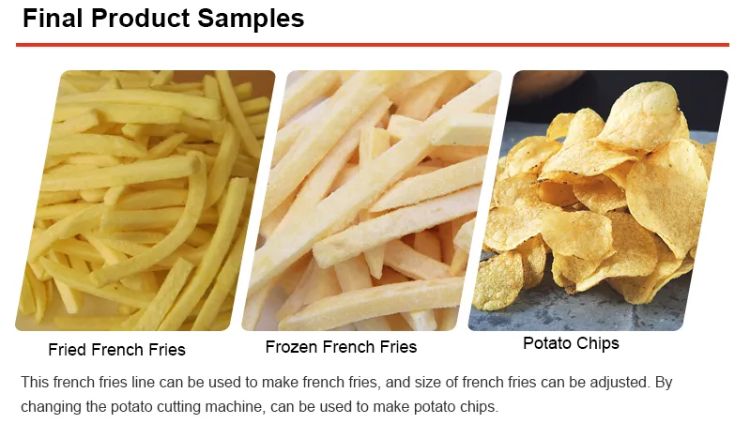

envoyez-nous une demande

Nous sommes un fabricant professionnel direct de machines de fabrication de croustilles ou de frites en Chine.

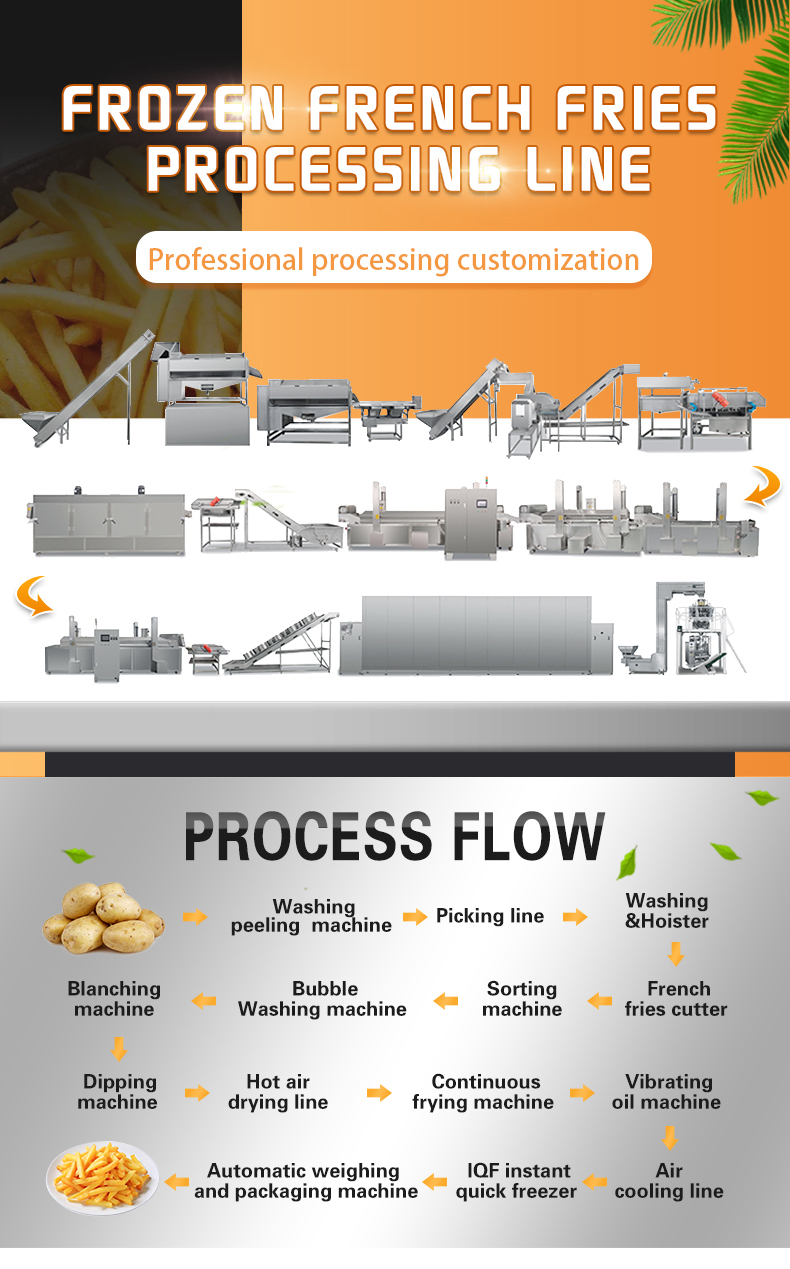

No. | Machine Name | Function |

1 | PVC Elevator | For elevating and conveying fresh potatoes into the next washing peeling machine |

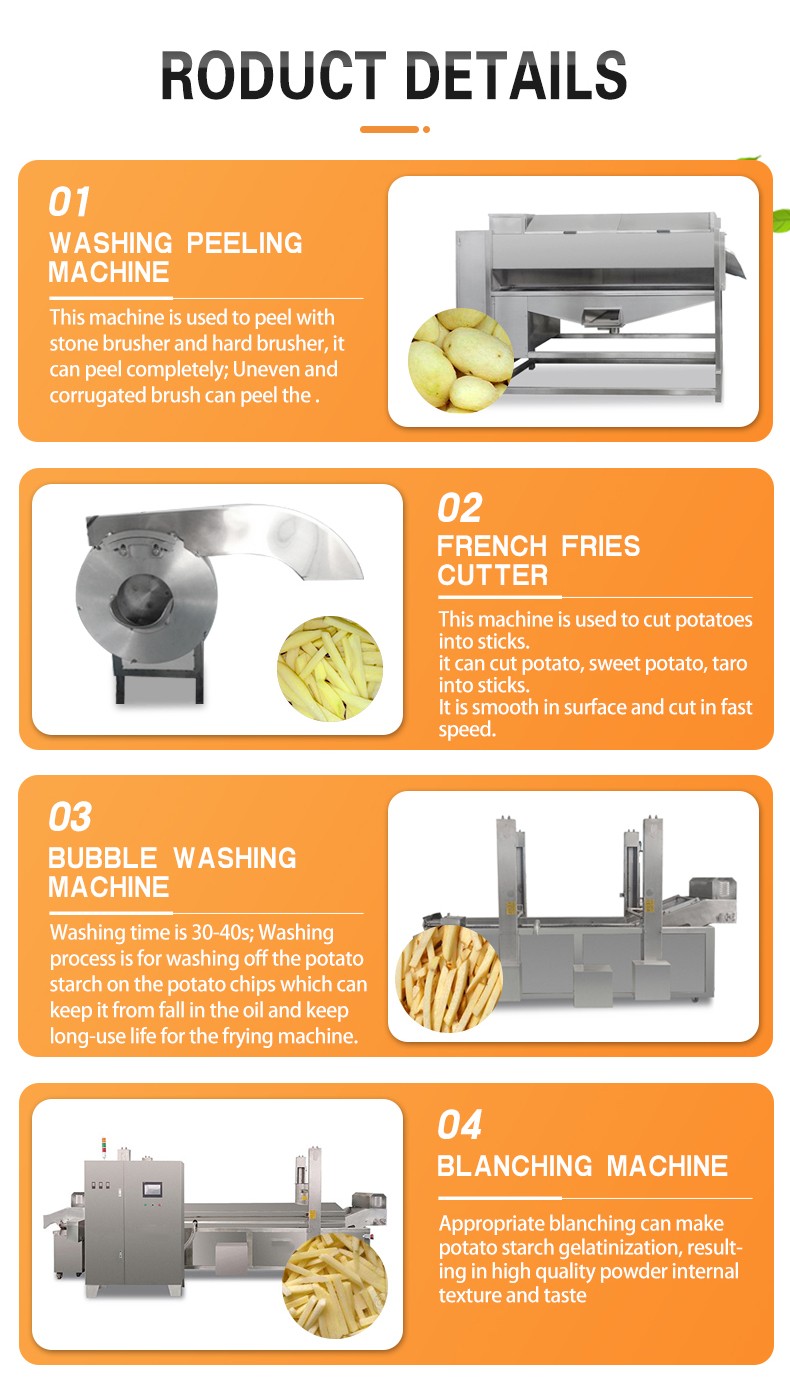

2 | Potato Washing and Peeling Machine | Thoroughly washing and peeling the potatoes |

3 | Sorting Conveyor | For manually disposing the uncleaned places and selecting the defective potatoes |

4 | Fries Cutting Machine | Cutting the potatoes into fries, sizes adjustable from 7*7 to 12*12mm |

5 | Water Tank Elevator | water as buffer to prevent fries breakage, and simply removing starch, meanwhile elevating fries into next step |

6 | Fries Sorting Machine | Automatically picking up the small pieces fries |

7 | Bubble Washing Machine | Through high pressure waterflow and water bubbles to impact and scrub the fries to wash off the starch |

8 | Blanching Machine | Through 60-95 degree hot water blanching to inhibit the activity of the enzyme and maintains the original vivid color of the fries |

9 | Vibration Dewatering Machine | Through vibration to remove the surface water and also to transport the fries uniformly to the next machine |

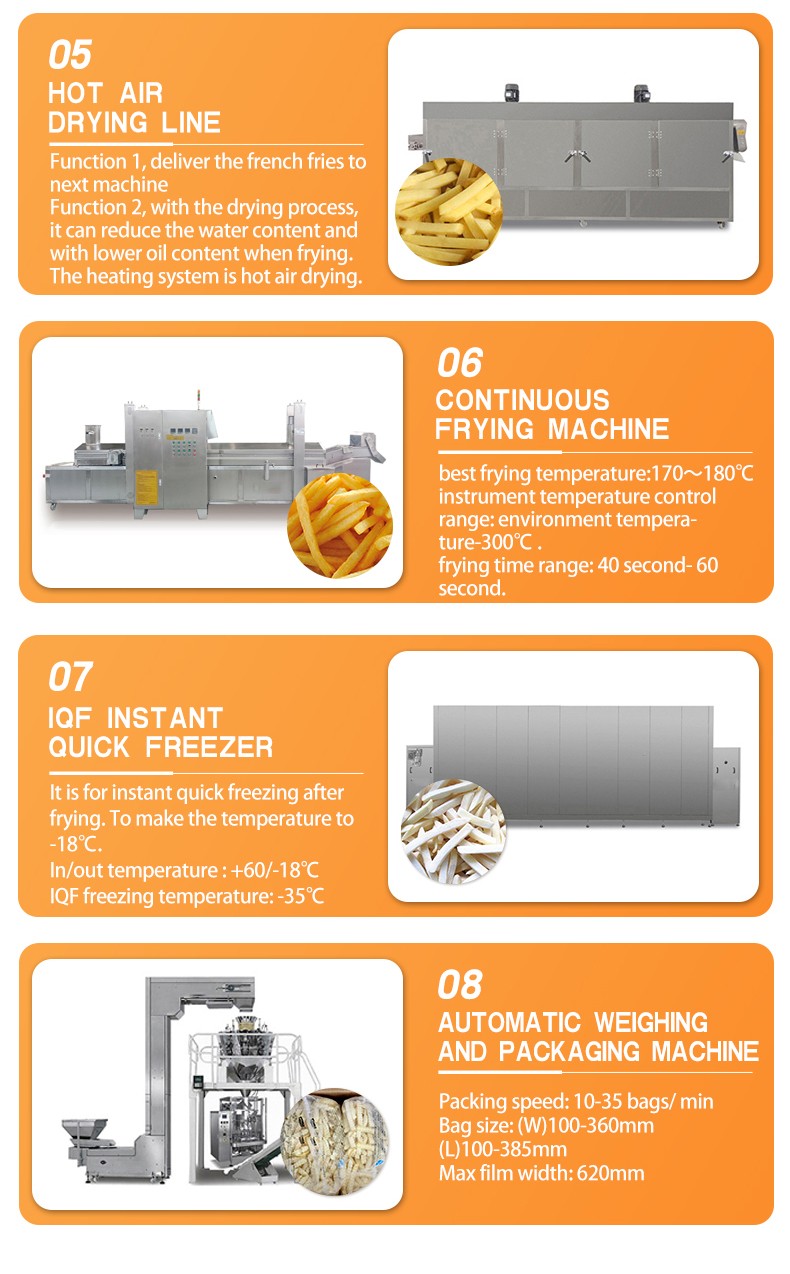

10 | Air Drying Machine | Through high pressure wind blowing for pre-cooling and removing the excess water in short time, effectively prevent the fried oil jumped phenomenon |

11 | Elevating Conveyor | For elevating and conveying the fries into next fryer machine |

12 | Continuous Frying Machine | For quick frying the fries around 40 seconds in 180°oil to avoid the adhesion and extend the shelf life |

13 | Vibration Deoiling Machine | Through vibration to achieve deoiling purpose, and also to convey the fries uniformly to next machine |

14 | Pre-cooling Machine | Through high pressure wind blowing for pre-cooling and deoiling the fries |

15 | Freezing Machine | Through mechanical vibration and wind pressure, the fluidized quick freezer floats products on stainless steel mesh belt, frozen products and prevent adhesion, achieve IQF |

16 | Automatic Packing Machine | For packing the finished frozen french fries |