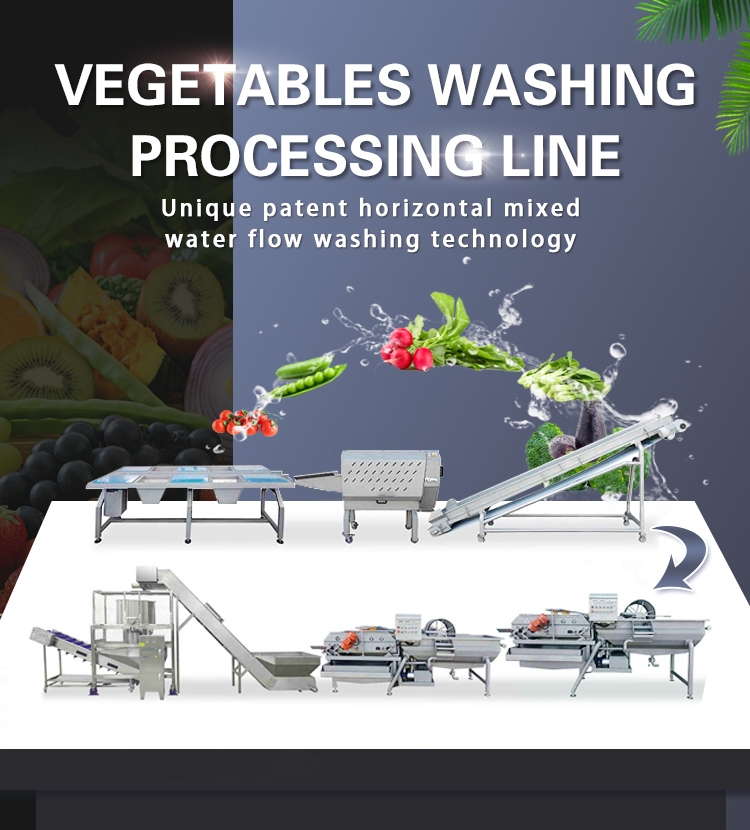

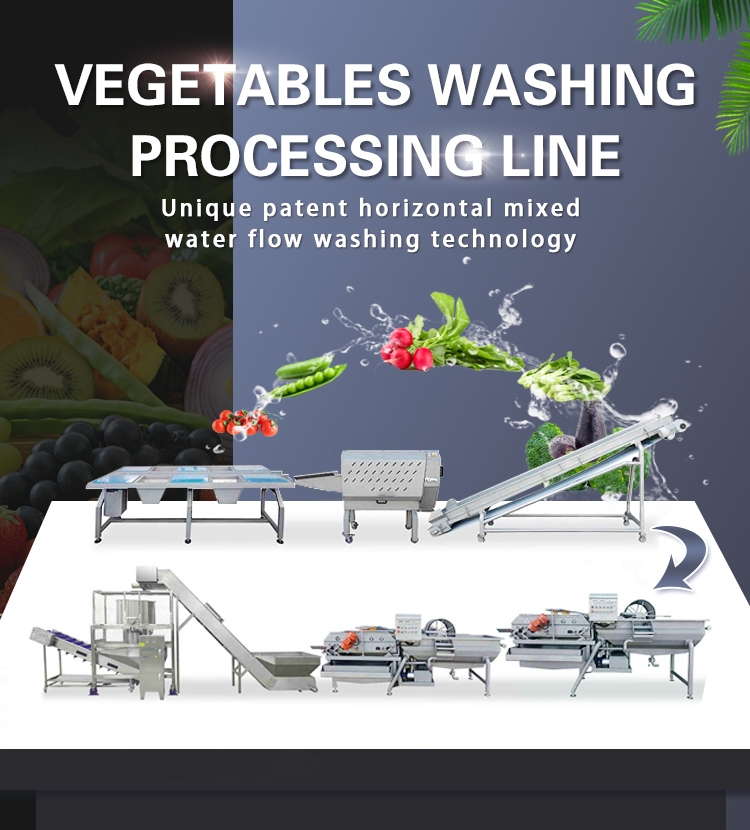

Raw material cleaning → vegetable cutting → blanching → dehydration → Stir fry → cooling → filling → weight detection →

sterilization → cooling → drying → Labeling → packing → palletizer - delivery

Product Name | Turnkey Project Fruit and vegetable processing, cleaning and packaging line |

Application | Processing of all kinds of vegetables, processing vegetables into semi-finished products. |

Operation mode | Fully automatic / semi-automatic (customized) |

Capacity | It can be customized according to the capacity |

Support bottle type | Box,Bag,Can,Bottle |

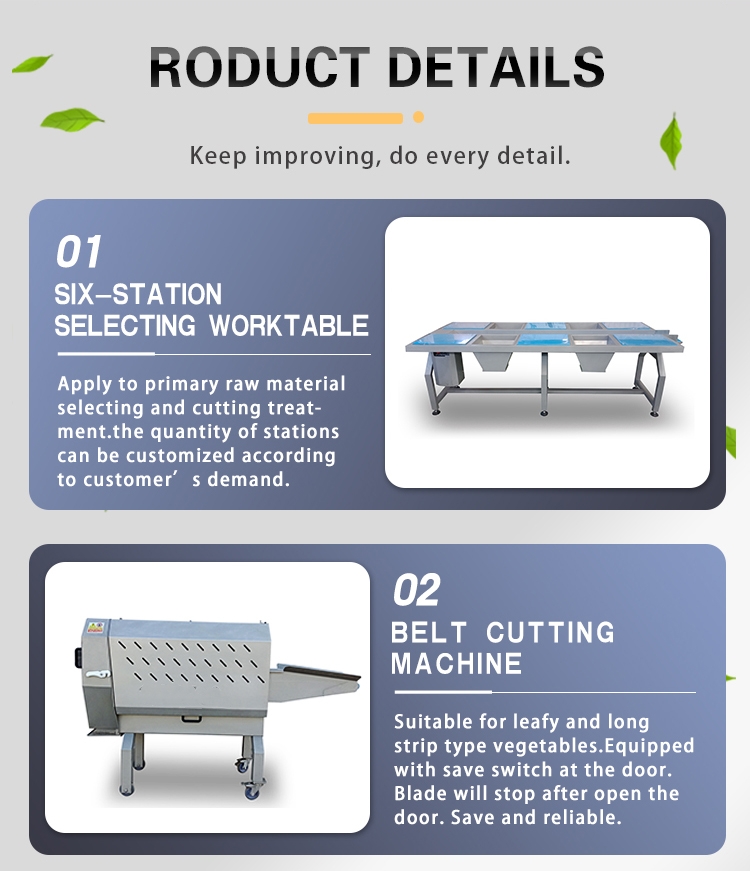

Name | Funtion&Specifications |

1. Bubble washing machine | Bubble(dry bean 0.5T--1T/H) |

2. Sorting size | Size of products |

3. Module Conveyor |

|

4.Module lifting Conveyor for waste material |

|

5. Lifting conveyor |

|

6.Conveyor | Used for product conveying |

7. Vegetables slicing machine | It can be shredded, sliced and diced |

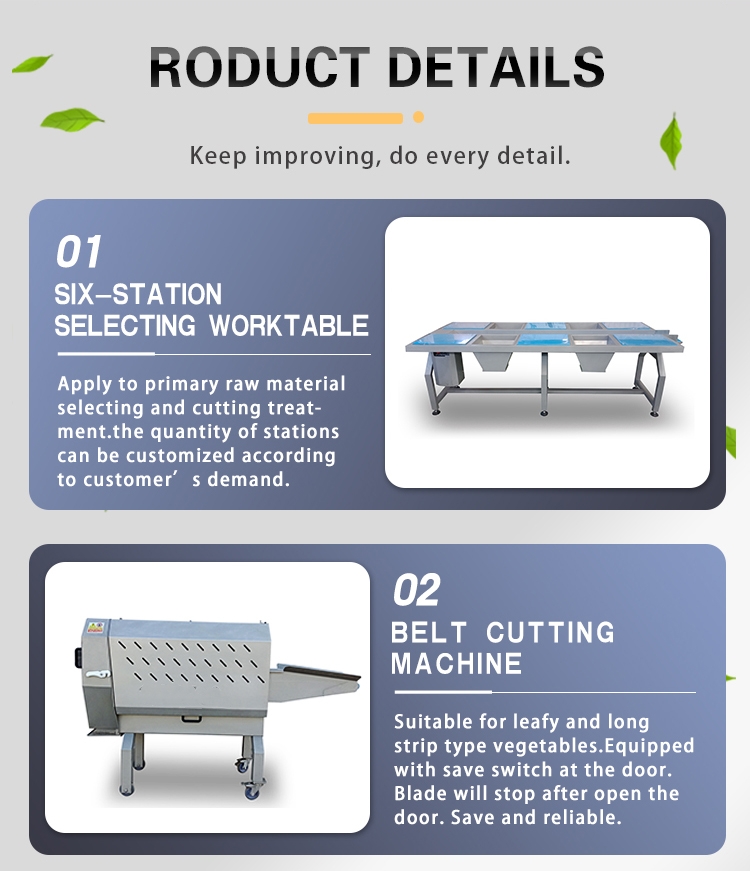

8. Belt Conveyor:select +dicing conveyor |

|

9. Manual worktable |

|

10.Blanching machine |

|

11.Cooling machine |

|

12.Dehydrator |

|

13.Stir fry | Wok, steamer, blender |

14.Sterilization machine |

|

Packing Line |

15.Full automatic filling machine |

|

16.Thermoforming&Vacuum Packaging Machine |

|

17. drying system |

|

18.labeling machine | Labeling bag or box |

19.date ink-jet printer | Date printing of cans |

20.carton erector |

|

21.case packer | Load the product into cartons |

22.carton sealing machine |

|

23.palletizer(can and carton) | Stack products together |

24. automatic wrapping machine | Wrap the packaged products together |