Fruit category: Apple, kiwi, banana, wood pineapple, persimmon, strawberry, grape, peach, pear, etc.

Vegetables: tomatoes, sweet potatoes, potato, beans, incense mushrooms, mushrooms, garlic, carrots, green peppers, pumpkins, onions, etc.

JuJube, Peanut, Aquatic products and livestock and poultry meat.

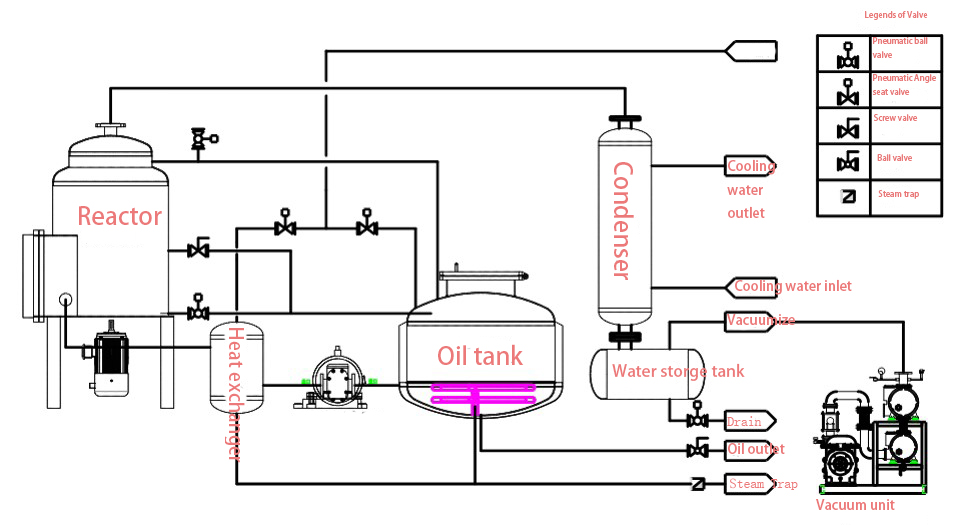

Low-temperature vacuum frying can prevent the deterioration of edible oils and fats, without adding other antioxidants, it can improve the repeated utilization of oil and reduce costs. Generally fried foods have a high oil content of 40%~50%, while the vacuum fried food The oil content is 10%-20%, the fuel saving is 30%-40%, and the saving effect is remarkable.