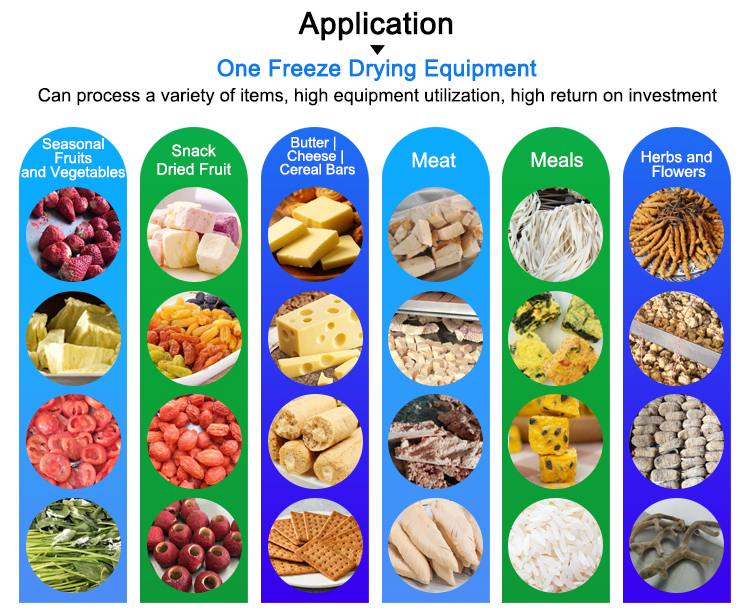

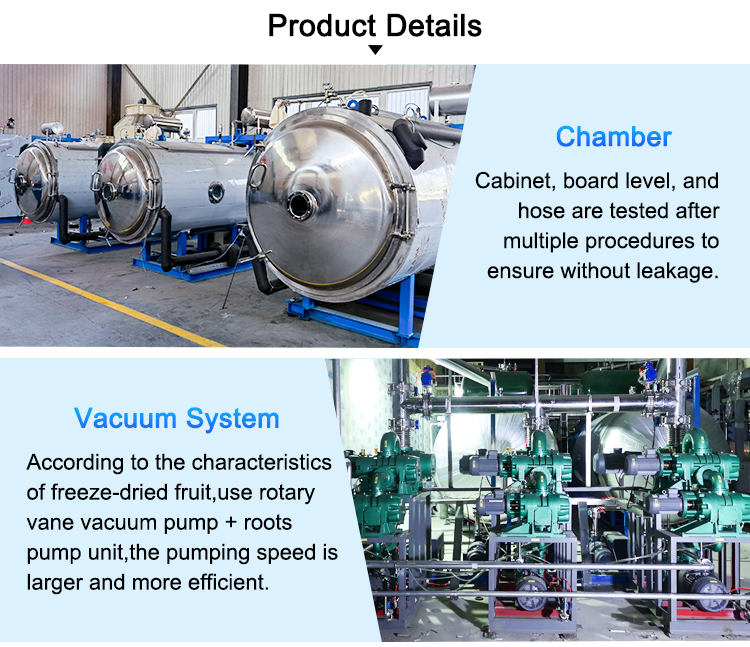

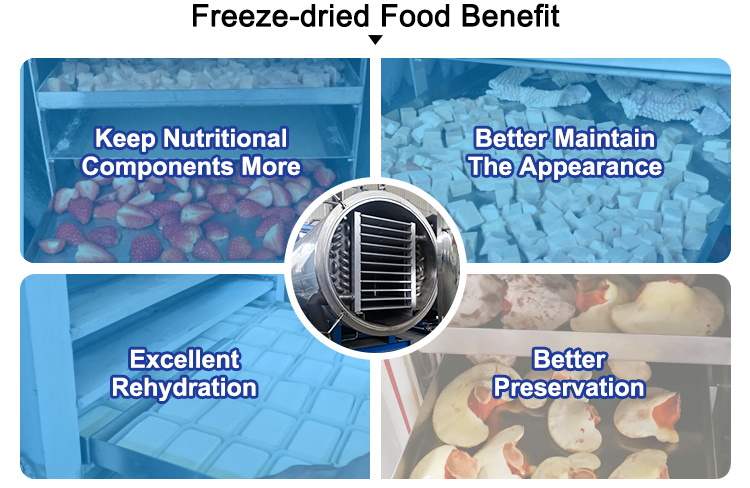

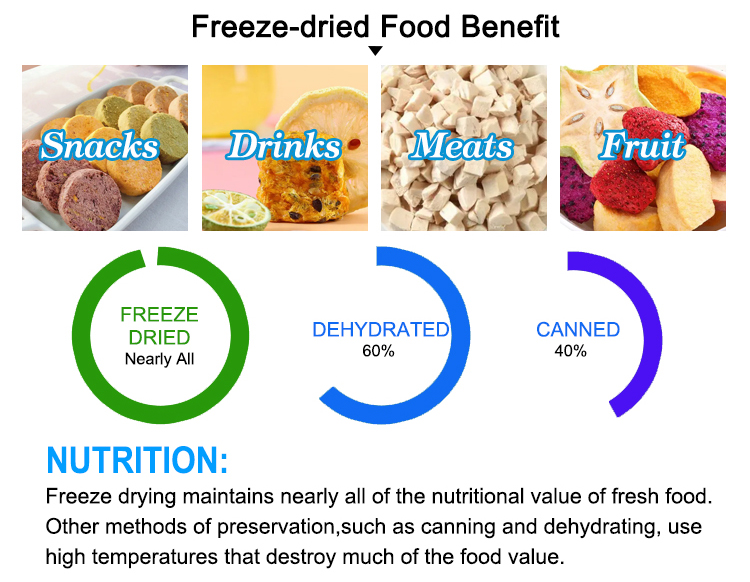

Vacuum Freeze Dryer Laboratory Lyophilizer Pharmaceutical Commercial Food Vegetables Fruit Dryer High Productivity LyophilizationThe vacuum freeze drying machine is an advanced method for the material for the material de-watering. It freezes the moisture material in the low temperature and makes the water inside sublimate directly in the vacuum condition. Then it collects the sublimated vapor by means of the condensing way so as to dewater and dry the material. Being processed by the vacuum freeze drying, the physical, chemical and biological states of the material are basically unchanged. The volatile and nutritious contents in the material, which are easy to be denatured in a warm condition, will be lost a little. When the material is freezing dried, it will be formed into a porous one and its volume be basically the same to that before drying. Therefore, the processed material can be recovered quickly if being watered again, because of its large contacting area and it can be stored for a long period in a sealed vessel.