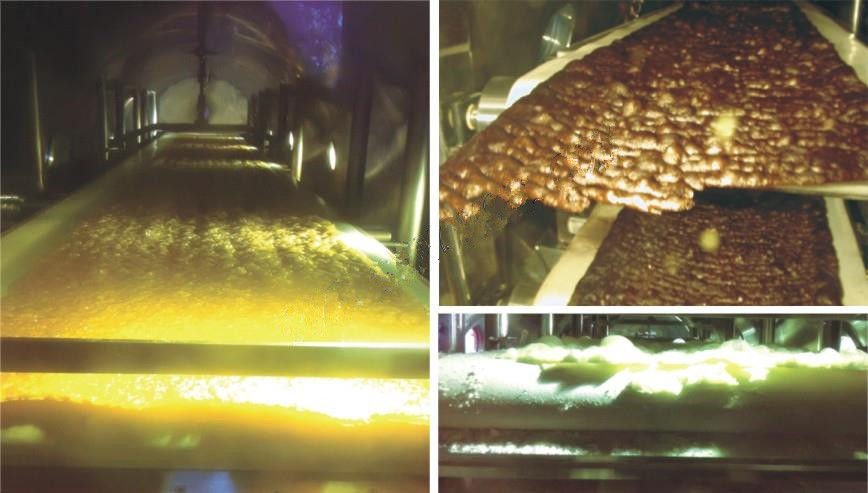

Vacuum belt dryer (VBD) is mainly used in drying many kinds of solid, liquid or paste raw material, such as traditional & western medicines, food, biological products, chemical material,

health foods, food additive etc, especially suitable for drying material with high-viscosity, easy agglomeration, or thermoplastic, thermal sensitivity, or material that can not be dried by traditional dryer.

For above materials, VBD is the best choice:

Pharmaceutical industry:chinese medicine extract, plant extract, egg embryo, PVPK series, fermenting liquid etc

Food industry:instant coffee, malt extract, carbohydrate, instant beverage, tea powder, cocoa powder, corn paste etc

Chemical Industry:lithium battery, emamectin benzoate etc.

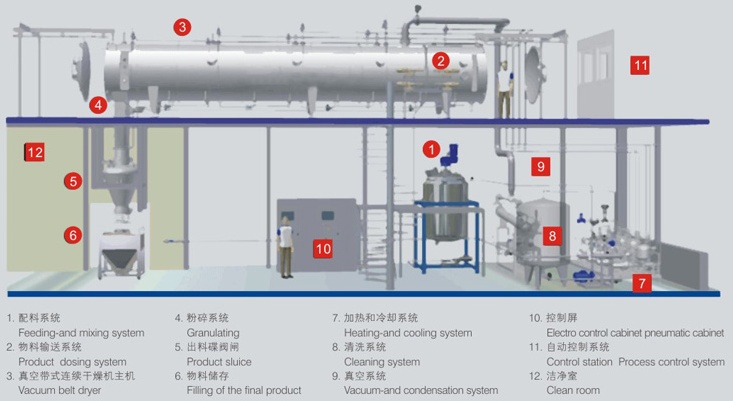

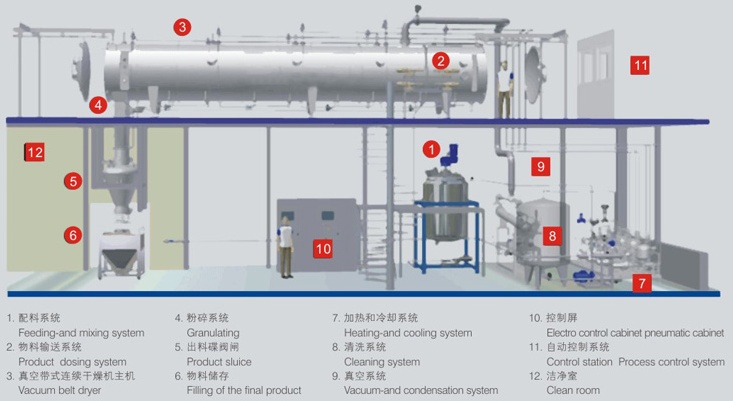

1. Main body structure is stainless steel sealing container, work continuously, feed material continuously, discharging continuously.

2. The unit heating source adopts hot water and pressured hot water, equipped with water cooling system. Heating source adopts steam and electric heating ways.

3. The charging amount can fine-tuning and auto control, even if in the condition of charging amount is so less, the coating device can coating uniformly, so as to optimizing drying technology;

every belt is equipped with solely screw pump as the feed pump.

4. The belts are imported Teflon belt, resist stick, resist chemical products, resist temperature from -70 ℃~260 ℃.

5. Due to the thermal sensitivity of natural medicine, adopts low temperature drying way, in the drying process the products temperature are generally at 40 ℃~50 ℃.

6. Vacuum belt type dryer adopts PLC control, through the PC man computer interface to operate the equipment, meanwhile in the discharge area and nearby of dryer set the operation panel

to operate in the work area. It can auto run and also can manual operation.

7. The unit has reasonable temperature measured point, and measured the temperature in time and reliable, and auto control the operation parameters.

8. The terminal outlet use the pneumatic vacuum butterfly valve blocked the vacuum then continuous drain out the drying material.

9. The discharge outlet has the function of smash and pelleting the dry power granular size can accord to the customer's requirement to set.

10. The unit equips the high pressure water cleaning device.

11. Vacuum auto belt type dryer are widely usage, and drying all kind of natural medicine extracts, include the thermoplastic products (polysaccharide, colloid, lipid ingredient, etc)

and other difficult dried products.

12. Vacuum belt type drying has the belt tension device (can set the tension) and correct errors device prevent the belt run deviation.

model | Effective area | layers | Price (10000 yuan) | Shell diameter Ф ×length×height | Water evaporation kg/h | monitor rate |

LD- 05 | 0.5m2 | 1 | 4 5 | 800×4500×2100 | 0.5-1 | 3.2 |

LD-1 | 1m2 | 1 | 50 | 800×4500×2100 | 0.5-1 | 3.2 |

LD- 1.5 | 1.5m2 | 1 | 55 | 900×5000×2200 | 1-1.5 | 3.2 |

LD-2 | 2m2 | 1 | 60 | 1000×5500×2400 | 1.5-2 | 3.2 |

LD-4 | 4m2 | 2 | 65 | 1000×6200×2400 | 3-4 | 4 |

LD-10 | 10m2 | 3 | 75 | 1200×7600×2700 | 7-8 | 7 |

LD-15 | 15m2 | 4 | 85 | 1400×7800×2900 | 10-12 | 8 |

LD-20 | 20m2 | 4 | 95 | 1600×7900×3100 | 15-18 | 8 |

LD-30 | 30m2 | 5 | 1 10 | 1800×8200×3300 | 24-27 | 10 |

LD-50 | 50m2 | 6 | 13 0 | 2000×9600×3500 | 40-45 | 14 |

LD-60 | 60m2 | 7 | 14 0 | 2200×9700×3700 | 45-55 | 15 |

LD-80 | 80m2 | 7/8 | 160 | 2400×10800×3900 | 65-75 | 18 |

LD-100 | 100 m2 | 7/9 | 1 80 | 2600×11500×4100 | 80-90 | 18 |

LD-120 | 120 m2 | 10 | 200 | 2800×12350×4400 | 100-110 | 19 |

LD-160 | 160 m2 | 10 | 280 | 2800×15500×4400 | 120-140 | 25 |

LD-180 | 180 m2 | 10 | 3 20 | 2800×17100×4400 | 140-160 | 25 |

LD-200 | 200 m2 | 10 | 360 | 3000×17650×4700 | 160-180 | 27 |