Main application

The machine is widely applied for the material crushing by the industries of pharmaceutics, chemical and foodstuff, etc .

Characteristics

The crushing chamber is equipped with wind wheel type high~speed rotating cutters, so that the airflow in the chamber is strong enough to eliminate any heat in the chamber.

It possesses the merits of smooth operating, dismantling and assembling, low noise and good crushing efficiency.

Working Method

The machine uses the wind wheel type high~speed rotating cutters and the fixed cutters to crush, mill and shear raw material, which is accompanied by strong airflow inside of the chamber

to bring out the heat with the finished products through the screen. The size of granules can be achieved by changing of the screen.

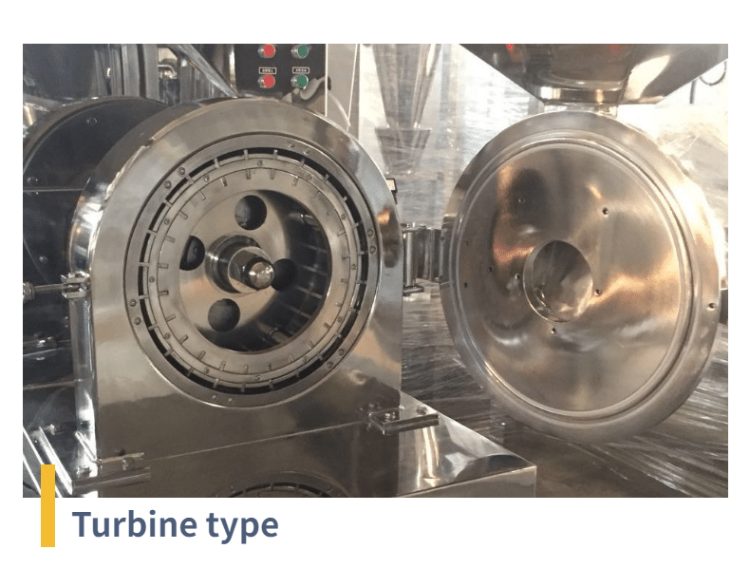

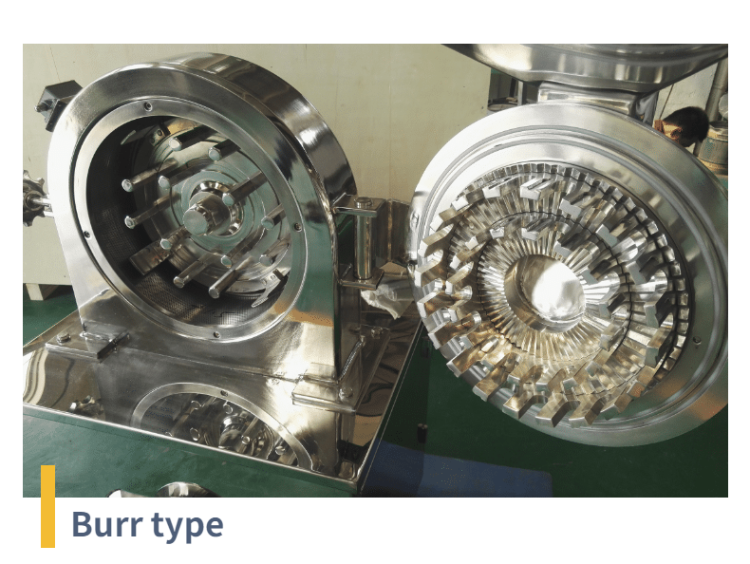

Inside the machine there are several groups moving knives (or prisms or hammerheads) in rotary wheel, and a group fixed knives in gear ring.

Within the cutting and collision of moving knives and fixed knives, the material was crushed. At meanwhile the grinding chamber has produced airflow,

which put heat and the finished product outflow together from the sieve and discharge.

Its strong cutter suit for grinding hard materials

Suitable for fibrous materials and heat sensitive materials

Suitable for fibrous materials

Suit for general materials

Model | Capacity (KG/H) | speed (r/min) | Feed size (mm) | Crush size (mm) | Power (kw) | Weight (kg) | Dimensions (mm) |

GY20 | 20-150 | 4500 | <6 | 12-120 | 4 | 280 | 590*650*1350 |

GY30 | 30-300 | 3800 | <10 | 12-120 | 5.5 | 350 | 650*800*1500 |

GY40 | 40-500 | 3400 | <12 | 12-120 | 7.5 | 480 | 800*950*1700 |

GY60 | 60-600 | 2400 | <15 | 12-120 | 22 | 650 | 950*1050*1900 |

GY80 | 80-1000 | 2200 | <15 | 12-120 | 37 | 1050 | 2500*1500*2100 |