- Home

- Products

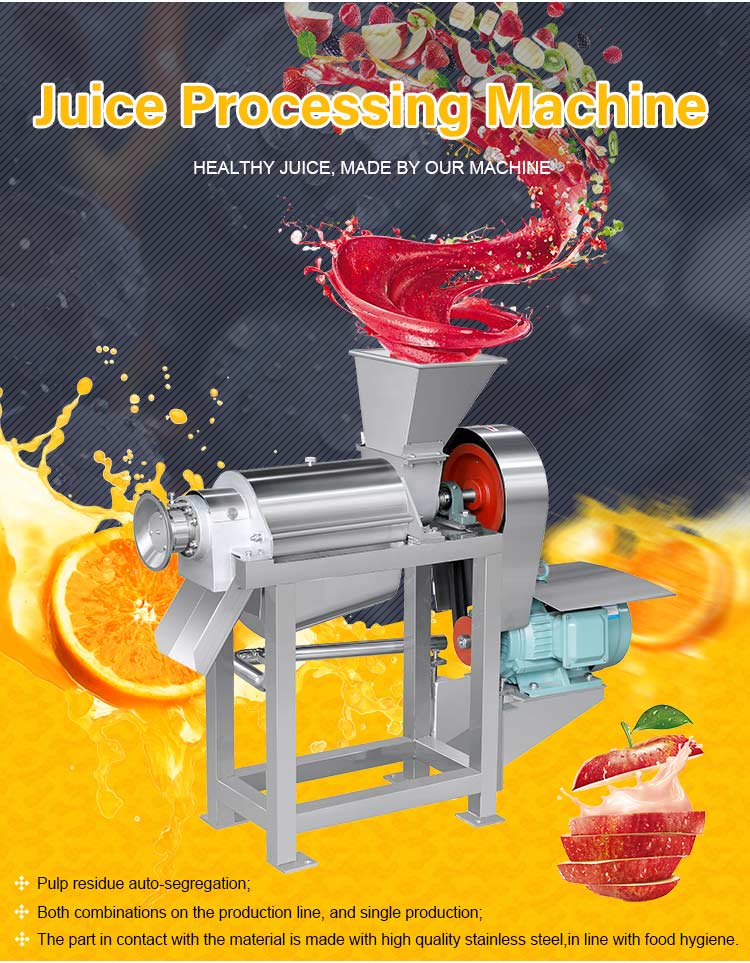

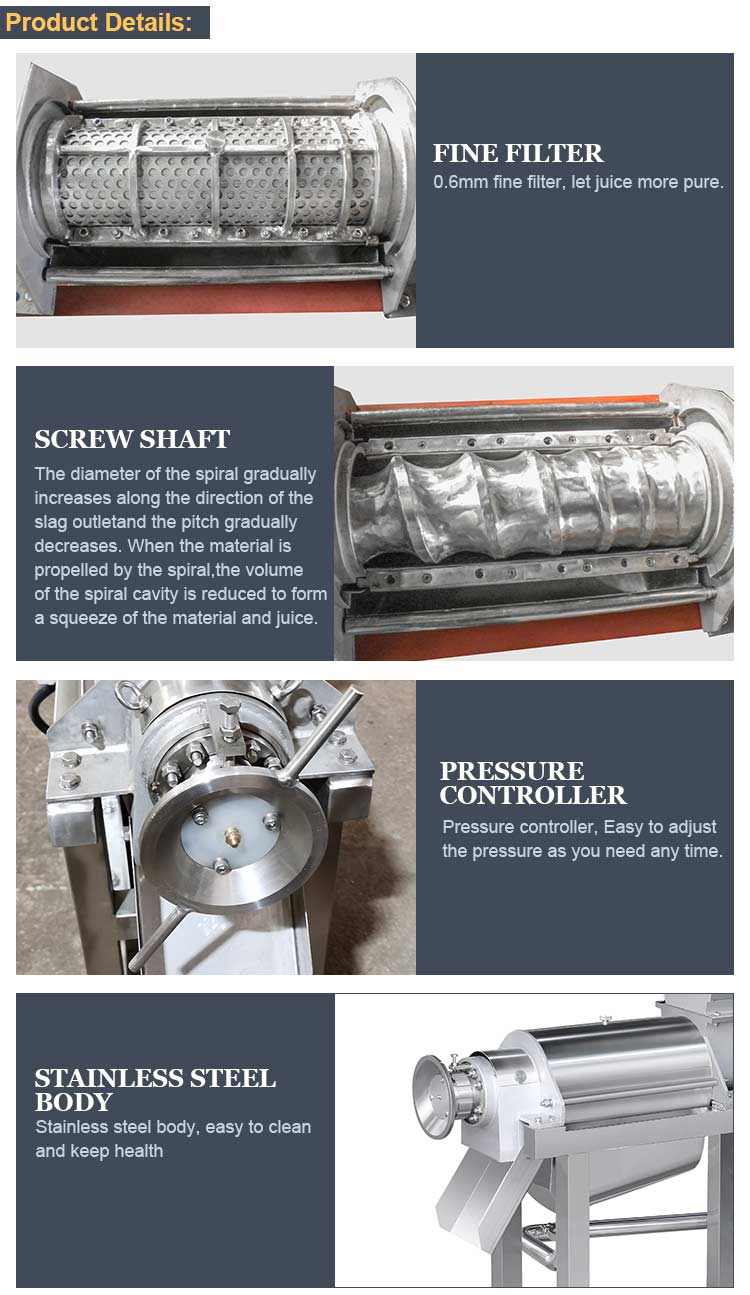

- fruit vegetable juice & puree processing machine

- Fruit vegetable Jam sauce paste processing machine

- Canned fruit vegetable processing line

- Fruit Chips & dehydrated vegetables processing machine

- Fruit vegetable pre-processing machine

- Frozen fruit vegetable processing machine

- Fruit wine vinegar processing machine

- Fruit powder,pectin & starch flour processing machine

- Fruit roll up & preserved candied fruit vegetable processing machine

- Filling & packing machine

- News

- About us

- Contact

- Home

- Products

- fruit vegetable juice & puree processing machine

- Fruit vegetable Jam sauce paste processing machine

- Canned fruit vegetable processing line

- Fruit Chips & dehydrated vegetables processing machine

- Fruit vegetable pre-processing machine

- Frozen fruit vegetable processing machine

- Fruit wine vinegar processing machine

- Fruit powder,pectin & starch flour processing machine

- Fruit roll up & preserved candied fruit vegetable processing machine

- Filling & packing machine

- News

- About us

- Contact